Aeroderivative Gas Turbine Maintenance

The hot air-and-fuel mixture moves through blades in the turbine causing them to spin quickly. Currently only one turbine is in operation.

How Can You Prevent Wear On Aeroderivative Gas Turbine Machinery With Atten2

Generally there are mainly three items regarded as gas turbine parts.

. Discover our product range heavy-duty industrial and aeroderivative gas turbines ranging up to 593 MW. An optional extended maintenance plan is availableincreasing boroscope interval by 2000 hours hot section inspection by 5000 and major inspection by 10000. Pressure ratios of the latest frame engines go as high as 301.

RR for the Portovaya station. Turbine meter sizes range from 38 inch to 4 inches. The turbine can operate on a wide range of liquid and gas fuels while minimizing NOx emissions at 15 ppm thanks to its DLE15 combustion system.

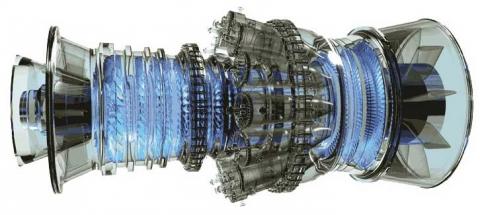

A compressor a combustion engine and a turbine plus other parts such as rotors casings and auxiliary. The earliest IGT 1939 had an efficiency of 18. Turbine meters are an ideal solution when high accuracy compact size fast response and high tolerance to shock and vibration are critical requirements.

Because of their versatility these turbine flowmeters are the solution for a wide variety of liquid and gas flow sensing applications. Rolls-Royces gas turbine-making operations were bought by Siemens Energy in 2014. Such compression ratios translate to gas-turbine thermal efficiencies in the 35 to 45 range.

After 1981 the ships were sold and refitted with what at the time was more economical. Rolls-Royces gas turbine-making operations were bought by Siemens Energy in 2014. Gazprom has also halted another Siemens Energy gas turbine at the station citing routine maintenance and the technical condition of the engine.

Siemens Energy gas turbines fulfill the high requirements of a wide spectrum of applications in terms of efficiency reliability flexibility and environmental compatibility. Spinning blades turn the drive shaft. Eight industrial aeroderivative gas turbines were originally manufactured by Rolls-Royce for the Portovaya station.

Eight industrial aeroderivative gas turbines were originally manufactured by Rolls-Royce for the Portovaya station. The gas turbine compresses air and mixes it with fuel that is then burned at extremely high temperatures creating a hot gas. Gas turbine parts are essentially identical but due to the difference in terminology for each manufacturer the naming process of gas turbine parts varies slightly.

Join our on-demand session to learn how GEs LM2500XPRESS gas turbine. As Fig 1 shows the compressor gas path narrows in going from the first to the sixth. The fast-spinning turbine blades rotate the.

Those for aeroderivative machines up to about 401. Hot gas spins turbine blades. GE has modular flexible aeroderivative gas turbine technology that can be installed in as few as 13 days to get power up and running fast.

The Gatric was an aeroderivative gas turbine based on the Metropolitan Vickers F2 jet engine. Its open configuration allows for faster accessibility easier maintenance and increased speed of engine removalreplacement. Reduction of fuel costs was successful using a different untested fuel in a marine gas turbine but maintenance costs increased with the fuel change.

Eight industrial aeroderivative gas turbines were originally manufactured by Rolls-Royce LON.

Aeroderivative Service Center Ge Power Careers

Why Aeroderivative Gas Turbines Make Sense For Cogen Power Engineering International

Gas Turbine Selection Heavy Frame Or Aeroderivative

0 Response to "Aeroderivative Gas Turbine Maintenance"

Post a Comment